Introduction

Like many, I have used double mid-side (DMS) from time to time and, doubtless less typically, I have used horizontal native B-format arrays too: I have written a couple of blog posts on the latter already. Given that DMS can be converted to horizontal B-format and vice versa, I have wondered why DMS is much more widely used and, more specifically, about the practicalities of mounting both arrays: in short, are the two advantages of DMS in use that a) it requires one fig 8 mic only (vs the two for native B-format) and b) that it lends itself better to compact mounting that fits more easily in a windshield? And if DMS is often achieved using this compact mounting – with the three horizontal mics clustered together – would it be better if implemented more spaciously, and with less difficulty in terms of mounting the rearward-facing cardioid, along the lines of a horizontal B-format array?

Now, fear not, this isn’t a blog post about the theoretical side of DMS (or, indeed, native/horizontal B-format) nor, for that matter, about why anyone should use it in preference to affordable ambisonic mic options (and there are compelling reasons): for that, you are much better in the care of Dr Helmut Wittke (CEO of Schoeps) and his colleagues in publications such as this: Wittek, H., Haut, C., and Keinath, D., Double M/S – a Surround recording technique put to test (Schoeps paper, 10.03.2010).

Rather, this post is about some of my dabbling with practical implementations of DMS rigs both generally and in the context – or constraints – of windshields, and with reference to the analogous horizontal B-format rigs. I include some examples of commercially available DMS mounts (past and present) along with some of my own solutions. I hope it isn’t too much of an idiosyncratic ramble, and that it may chime with or, even, be useful for others.

NB having drafted much this blog post I found it rather long and, also, dividing into a few key sections, so I have divided into three separate blog-posts. This one, (part one), is concerned purely with the rigging options: my take on the options for how to mount mics for DMS. It is concerned with SDC mics and, also, doesn’t go into DMS with shotgun mics: it is primarily focused on rigs suitable for taking into the field (i.e. in windshields). Part 2 concerns practical comparison of the different rigs, not least exploring the reality of shadowing effects caused by mics sitting close to other mics. Part 3, to follow very soon, explores the practical differences between DMS and horizontal B-format set ups: there is so much in common – and conversion from one to the other is simple mathematically – but what are the practical pros and cons? Parts 2 and 3 include sound samples that you can download and play with.

Different mic mounting options for DMS

When using small-diaphragm condensers (SDCs) there are three main ways you can configure the three mics needed for DMS:

1) end-address mid mics combined with a side-address fig 8, so that all three horizontally-oriented mics are aligned vertically (typically the central mic is the fig 8, but not always so);

2) end-address mid mics combined with a side-address fig 8, so that all three horizontally-oriented are clustered more closely than in option 1, forming a tightly spaced triangle, but with the two mid mics horizontally offset from the centre of the array (the fig 8 can be above or below the mid mics); and

3) side-address mid mics oriented vertically, flanking, from above and below a horizontally-oriented fig 8.

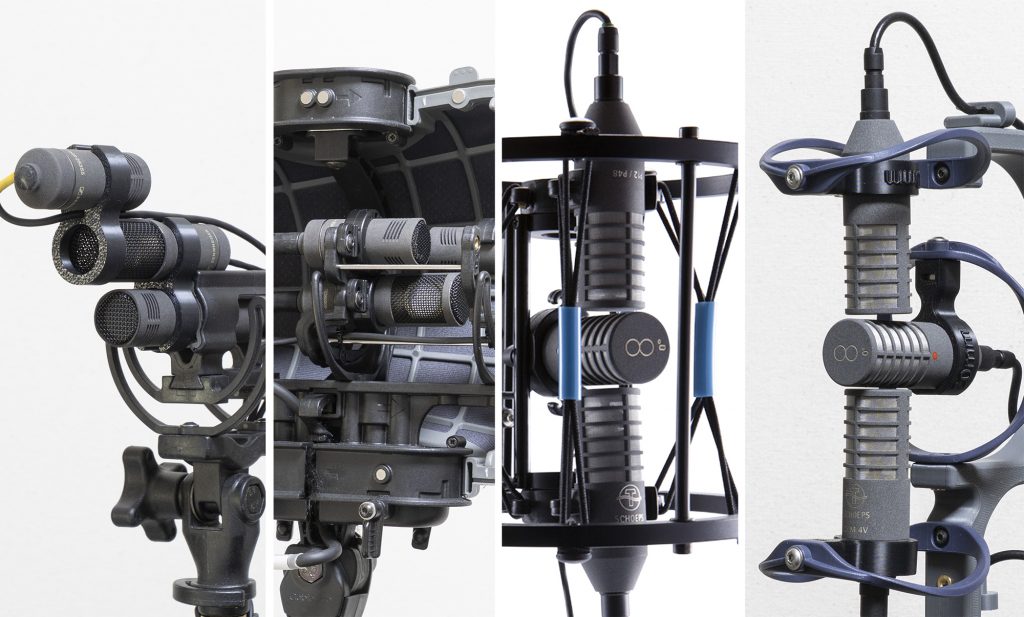

These three configurations are shown with unmounted mics in the image below:

The composite image above shows that, with the end-address mics (options 1 and 2), the forward-facing mic and fig 8 are easy to mount in the manner of a simple mid-side pair, with the complexity coming from the addition of a rearward-facing cardioid, the body of which projects awkwardly away from the front of the other two mics. In a studio context this can be supported by a separate mount and stand, but this still requires fiddly alignment and is a real pain when adjusting the location of the array to the best position. Obviously, mounting the three mics together is more practical and, indeed, is essential for use in the field in a windshield.

Option 1 – end-address cardioids, all aligned

This option with the three mics aligned vertically, is perhaps harder to rig, but with shorter mics (such as Sennheiser MKH 8000 mics with MZLs, and Schoeps CCM mics) it is more feasible. Cinela, for one, has effective windshield mounting solutions shown below, where in each example the rearward-facing mic is supported by pairs of thin struts to reduce acoustic impact. In both these designs the central mic has a long plastic holder to extend the mic to the quite widely-spaced OSIX isolators, necessary to counteract the mass of the three mics at the front.

Of course, where DMS rigs involve a shotgun for the forward mic, then the fig 8 and the rearward facing cardioid can be clipped above and below the long body of the shotgun: this is a not entirely satisfactory use of DMS given the polar pattern of a shotgun mic and the irregular response off-axis arising from its interference tube. With a little bit of head scratching and some 3d printing, similar options can DIY’d, although any shock-mount needs to be able to counter the front-heavy loading.

Option 2 – end-address cardioids, side-by-side

This mounting option, where the two end-address cardioid mics are positioned side-by-side, has become a common approach. As with the vertical configuration (above), mic length can quickly make things unwieldy: even the modest 78mm length of the Rycote CA-08 cardioid, plus a low-profile XLR connector, makes for a rather long projection of the front (rear-facing) mic, as shown here:

The more diminutive Sennheiser MKH 8000 mics with MZL connectors instead of XLR modules are, of course, the intended mics for my Rycote Cyclone DMS Kit 1, and show rather better the more compact end-result of the side-by-side cardioids in this option :

The constraints of the hoop size (which precludes vertical alignment) meant I also adopted this approach with my DMS mount for MKH 8000 mics in the diminutive Radius Windshields Mini-ALTO 115. As with the Rycote Cyclone DMS Kit 1, this uses thin stainless-steel bars to keep the clips aligned, but also uses the small front ring of the MKH 8030 fig 8 as a fixing point for a clip: it is workable if you need an extremely compact DMS array in a windshield, but is a bit fiddly to set up. Moreover, unlike MS pairs in the Mini-ALTO, DMS rigs in this windshield – or at least my attempts! – end up with the fig 8 mic between the hoops, so that the sideward-facing lobes of the mic are aimed directly at the rather chunky plastic ring where the two windshield pods join: obviously not ideal.

While this configuration for DMS is arguably easier to mount and is certainly more compact, there are two obvious downsides. First, the coincidence of the mics in the horizontal plane is lost, with both cardioid mics horizontally offset from the centre of the array. Given how much care is usually taken with MS rigs to ensure that the capsules of the two mics are aligned vertically, to ensure coincident time of arrival (and phase coherence) of sounds from the (usually predominant) horizontal plane at the two mics, this might seem problematic for higher frequencies (depending on spacing, but typically above c.10kHz). Such concerns are often over emphasized by the theorecticians, however, and in practical use – even recording, say, classical music – the effects of even side-by-side MS pairs are not always evident: one to bear in mind and check for your usage and ears, perhaps. The second downside, is that the mics are more obviously shadowing each other than when positioned exactly vertically above each other. The physics are undeniable, but, again, whether it matters or not will come down to how critical the recording is and the nature of the sound source. I will explore this – with sound samples – in Part 2 of my DMS blog-post series. And, of course, mic size comes into play: for example an MKH 30 + 2 x MKH 40 MS rig is quite a different beast to the MKH 8030 + 2 x MKH 8040 rig, especially if the latter uses MZL connectors as in the photos above. And you can take the miniaturization of the cardioid further: below is a photo of my Nevaton DMS rig using their new diminutive MC59uS/C2 cardioid mic, which is only 23.5mm long, with their MC59/8 fig 8. In this case the mics are too wide (22mm diameter) to fit in a Radius hoops (and are here shown on a Rycote Nanoshield shock-mount, although would work in any Rycote or similar windshield), but the difference in size between the fig 8, with its XLR connection, and the tiny cardioids makes mounting a bit easier and, of course, any shadowing effect is reduced to some extent by the shortness of the cardioids. On the downside, the MC59/8 has no front part to be used for support as in my MKH 8030-based DMS rigs above.

Option 3 – using side-address cardioids

This mounting option, using side-address cardioids, used to have two commercially-produced options in the form of the Cinela Z-DMS-CCM (for the Cinela Zephyx, launched in 2005) and the Schoeps/Rycote WSR DMS LU (introduced by 2005), which were both designed for the Schoeps CCM8 + two CCM4V combination. The Schoeps/Rycote mount is certainly discontinued, although I understand that the Cinela mount, although no longer on their website, is still produced occasionally as a special item: make certain you ask nicely! The Schoeps option was used to illustrate Wittek et al’s paper on DMS and appears to have been Schoeps’s preferred implementation of DMS for some time, but currently the DMS options on their website use end-address mid mics either in Rycote Cyclone or Cinela Pianissomo windshields. The Schoeps/Rycote and Cinela methods of rigging the DMS setups with side-address cardioids are quite different as you can see from the photos below:

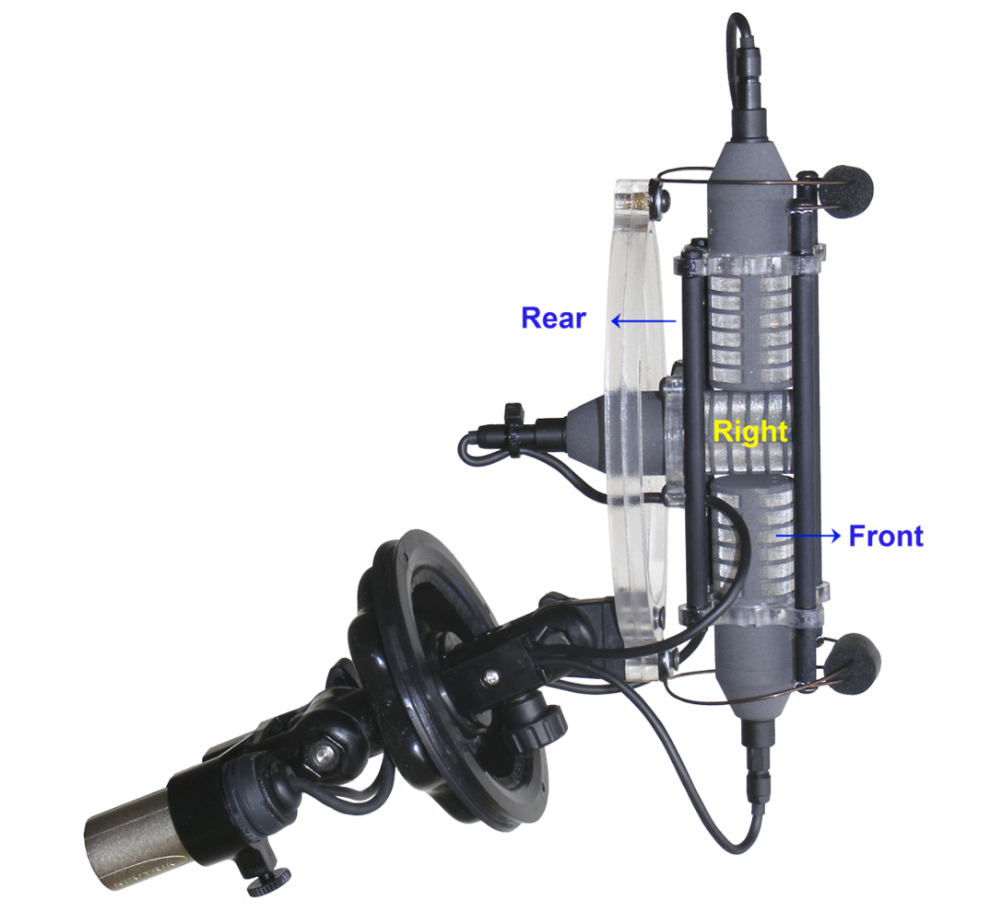

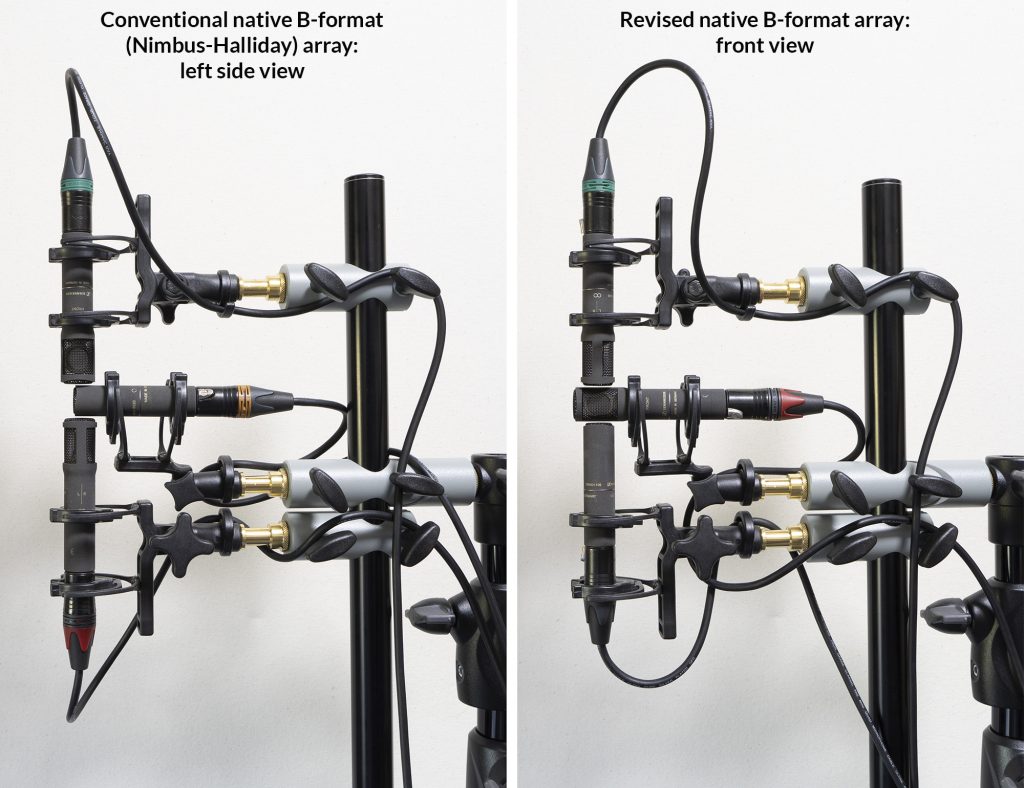

I came across both these mounts for DMS with the side-address Schoeps CCM4V only more recently when wondering if my thoughts on adapting the approach taken for horizontal B-format rig to DMS had any precedents: evidently, there is nothing new under the sun! Of course, both the Cinela and Schoeps/Rycote mounts could be used for horizontal B-format too, but I have no idea if that has ever been done: you would hope so.

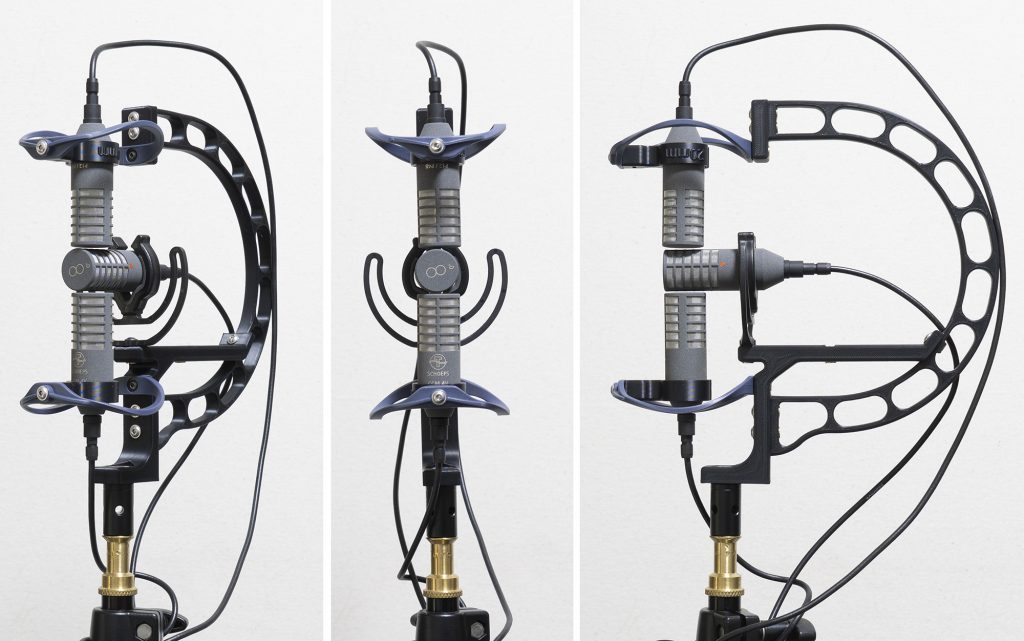

Coming at my own attempts for DMS with the side-address Schoeps CCM4V (and I am grateful to Schoeps for loan of the mics to test this) was, of course, from the perspective of using horizontal B-format either without any windshield (e.g. for location music recording, as with my bagpipe recordings last year) or within one of my Mega-Blimps. The latter, being much larger than windshields used with the commercially produced mounts, mean that a) the windshield basket can be oriented as designed and b) there is scope to reduce the proximity of structural supports around the mics. If the advantage of using side-address cardioids is that one can avoid the cluster of mics and consequence colouration arising from using end-address mics for the most demanding and critical applications, then it seems worth keeping the mics as free as possible of other sources of colouration, be that the windshield basket structure or the supports for the mics. Anyway, that is the rationale behind my DMS mount for the Mega-Blimp, albeit with a balance struck between transparency and isolation from structure-borne noise: i.e. the mics need shock-mounts (in this case mainly Radius Windshield hoops, but also using Rycote lyres where this reduces obstructions in front of the mics). The result does look similar to the horizontal B-format mount, although there are some significant tweaks to the geometry of the design to better fit the three Schoeps mics than the MKH 8000 mics.

Of course, such mounts that aim to minimize colouration are quite large, especially the revised version with its deeper rearward projection, but they fit happily in even my standard-sized Mega-Blimp, which, of course, minimizes additional colouration with its sparse and thin (mostly 3mm diameter) basket structure.

As with the horizontal B-format mic, such a rig presents challenges for the rear-facing upper mic, which here, as with the Schoeps/Rycote WSR DMS LU, has some on axis obstacles, in this case being the hoop and mic clip of the central mic, quite close to the cardioid, and beyond that the 18mm-wide vertical element of the mount. Looking at this more closely, it is, of course, possible to remove the hoop and mic clip by swapping to a Rycote lyre, which supports the fig 8 mic from underneath (and I have made provision in the mount for use of a rear lyre with a 9.5mm mount for the Lemo connector). And the impact of the 18mm-wide rear bar can be addressed by making this much thinner – in this case a slim 8mm (I tried 6mm, but that seemed too flimsy) – and also by moving this further still from the mic. There’s no such thing as a free lunch, however, with the downside of this version being less lateral stiffness for the arm to the upper mic (so not one to use if the mount is being subjected to much vibration). This revised version can be seen below.

For windshield use only, of course, it is possible to remove the need for an arm extending upwards to the top mic by adopting the approach previously used for one of my horizontal B-format rigs, which removes obstacles in front of the topmost (i.e. rear-facing cardioid) mic without the penalty of introducing more wobbliness to it.

So here we have it: an exploration of the three configurations used for DMS with SDC mics. Commercially available solutions exist for the first two options (with end-address cardioids), but are thin on the ground, to say the least, for the third option (with side-address cardioids). In all three cases there is significant scope for DIY solutions: indeed, for any particular mics this might well be essential. Hopefully some of my ramblings – or at least the photos – might inspire others to their own DMS solutions. Meanwhile, stay tuned for the practical comparisons in Part 2 and Part 3.