TIG welded cage

Sometimes, however impractical it seems, it is useful or at least tempting to get a low-noise large-diaphragm condenser (LDC) microphone pair outside. Various set-ups have been tried over the years by nature recordists, often taking advantage of a pair of the affordable and low-noise Rode NT1a mics. I have been particularly impressed by Magnús Bergsson’s recordings with NT1a mics, not least as he often runs these in parallel to Sennheiser MKH20, 30, 40, 8020 and 8040 mics: see his website at HLJODMYND – SOUNDIMAGE.

For use when I need lower self-noise than provided by my usual small-diaphragm condenser (SDC) options, I wanted a mid-side pair of LDC mics (i.e. a coincident stereo pair comprising a figure-of-8 mic for the sides and, in this case, a forward facing cardioid mic), so having a Rode NT1 (the more neutral successor to the NT1a: 4dBA) and a Rode NT2a (7dBA) to hand I have put together an oversize windshield or blimp for a vertical mid-side set up.

For better stiffness than the usual plastic, I have gone for TIG-welded stainless-steel wire (2mm diameter), with the blimp cage incorporating (isolated) spigots to fit a Manfrotto 154 stereo bar. The blimp disassembles into two halves, but, in reality, I just leave it assembled and insert the mics through the spaces in the cage. For the covering, I have gone for Rycote’s red lining cloth and Rycote long fur (all supplied by the metre direct from Rycote: amazingly helpful people there), with the usual elasticated drawstring tightly closing the side opening. The cage was built to my design by a friend of mine, who works with stainless steel wire for rolling-ball sculptures – all for a few pints of beer – and the fur covering was made by another friend with professional sewing skills.

Blimp with fur

Initial testing met expectations, not least with the better windnoise attenuation resulting from a larger diameter windshield than those usually designed with necessary compromises for boom-pole use: it’s the distance from the sound generating surface (the outer side of the blimp) that matters, with the inverse-square law applying.

Needless to say, I am by no means claiming this as a sensible/feasible option for most usage (and I have much more practical alternatives for most projects): it is heavy and I wouldn’t want to carry it and its stand (I use a Manfrotto 1004BAC) more than half a mile or so. There are, of course, many lighter, more robust and less humidity-sensitive microphone solutions that will be preferable for most projects (e.g. a Sennheiser MKH 30/40 pair).

However, this DIY approach might be of interest to anyone else was thinking along similar lines with LDCs (and there is no need to be afraid of getting large studio mics outdoors): LDC mid-side arrays are feasible for such use and it makes good sense to consider (affordable) purpose-built windshields as alternatives to shoe-horning LDC mics into undersized windshields or adaptation of less than ideal items from the local DIY store!

In action, recording musicians in the grounds of Mannington Hall

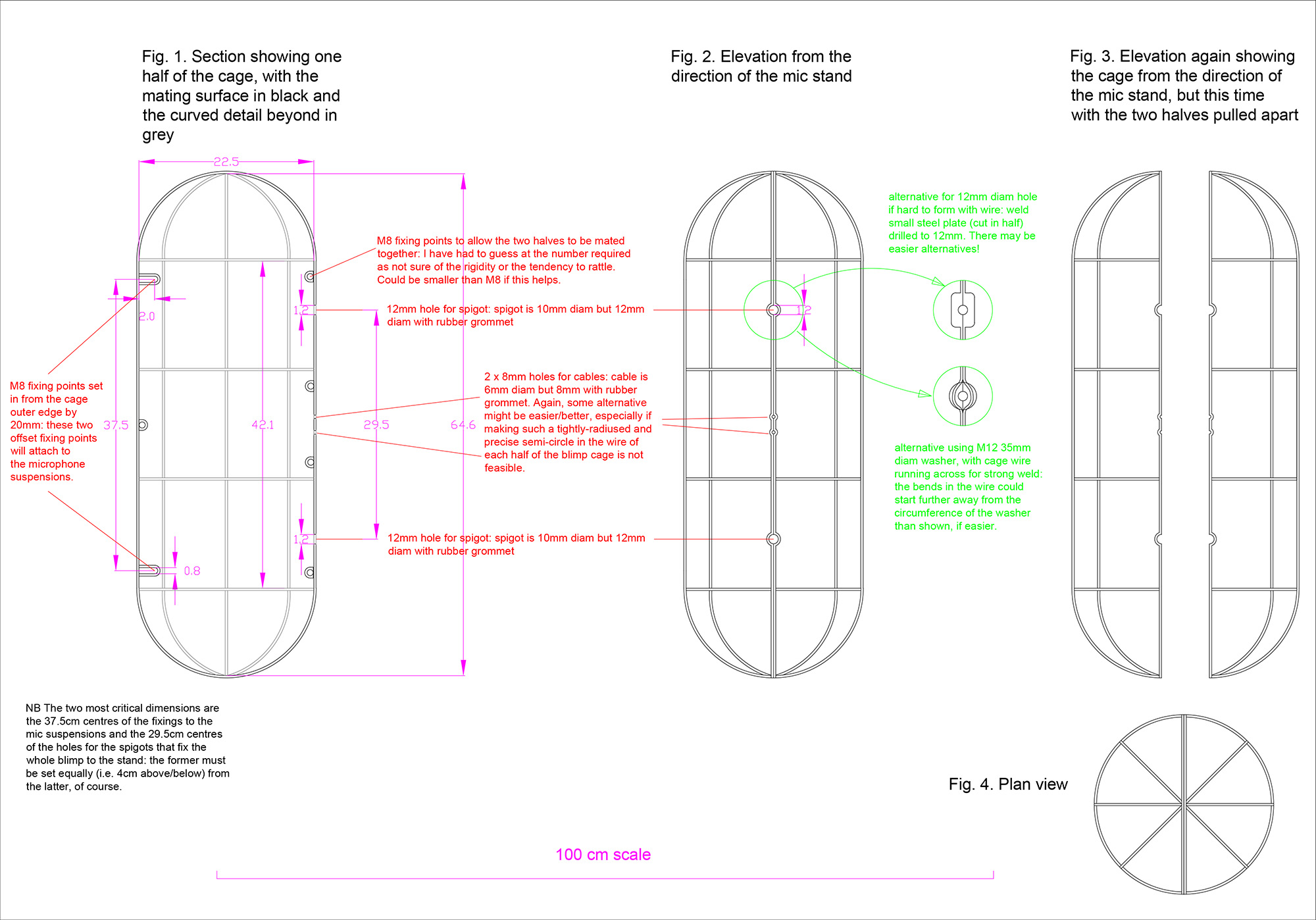

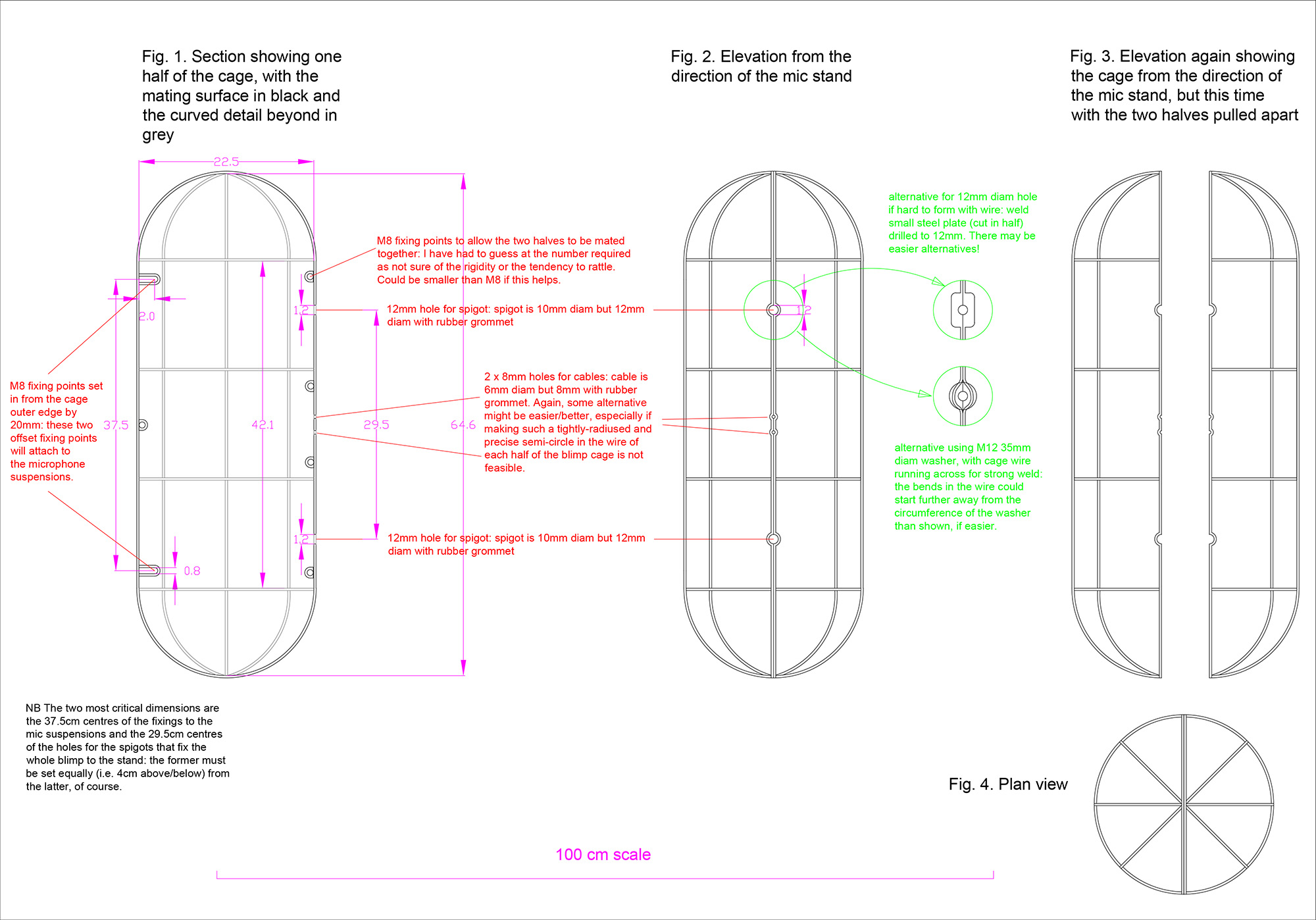

And for anyone really keen, here’s my design